NX includes well established capabilities for 3D annotation, and Siemens’ customers worldwide are actively utilizing and endorsing 3D annotation on their solid model designs. Supporting all the major concepts and requirements defined in ASME Y14.41, this comprehensive list of capabilities in NX 5 provides the most complete collection of tools offered within a CAD product to date, and further enhancements are being developed.

NX 5 collects these capabilities under a menu selection that contains all the tools necessary for making 3D models the master repository for all product and manufacturing data.The PMI toolbar provides a single, unified interface for creating, editing and querying PMI on the solid design. In addition to facilitating the creation of 3D product definitions, this tool will check models for compliance with the ASME standard, offering the options of stringent and relaxed compliance levels.

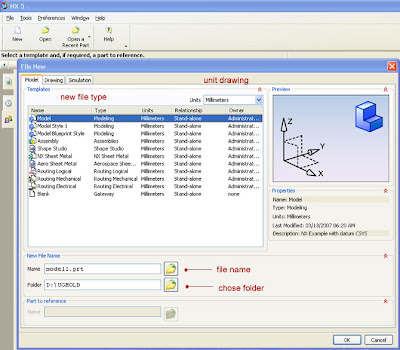

CAD APPLICATION

With a comprehensive range of computer aided design (CAD) applications, NX is unmatched in power and flexibility when it comes to mechanical design and engineering. NX offers a broad set of CAD solutions for the design of complex mechanical products – including dedicated solutions for processes like routed system design, sheet metal design, and plastic part design – that deliver higher efficiency and shorter design cycles at lower costs. NX enables design professionals of any skill level to consider more alternatives, evaluate them more thoroughly, and get to market with innovative designs of superior quality.

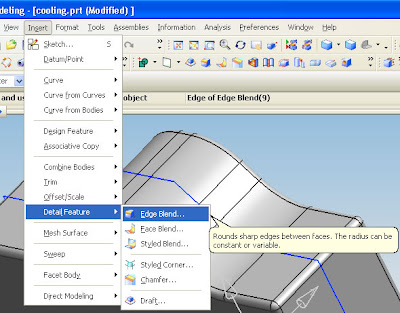

NX design applications include tools for:

* Human Modeling

* Modeling

* Assembly Design

* System-based Modeling

* User-defined Features

* Routed Systems Design

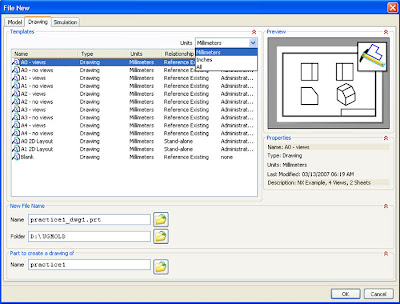

* Drafting

* Sheet Metal Design

* Flexible Printed Circuit Design Fact Sheet

With NX, efficiency and cost savings extend far beyond the design process to all phases of product development. NX dynamically integrates CAD design with planning, simulation, manufacturing and other develpment processes to help ensure that design decisions can be made more quickly, with detailed knowledge of product performance and any potential manufacturability issues.

Productive

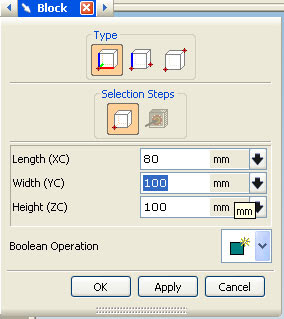

Complex products and processes demand user interactions and workflows that reduce complexity. NX streamlines decision-making by providing critical information where it is needed. Intelligent user interfaces provide dynamic feedback that accelerates design workflows, whether you are interactively creating product models or weighing performance and manufacturing cost trade-offs.

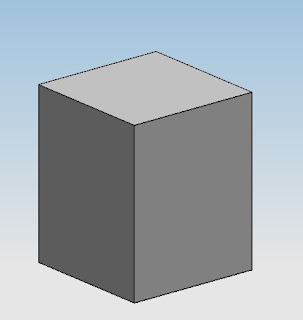

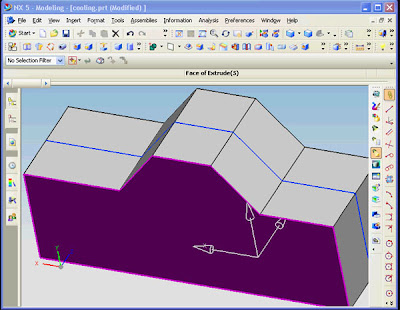

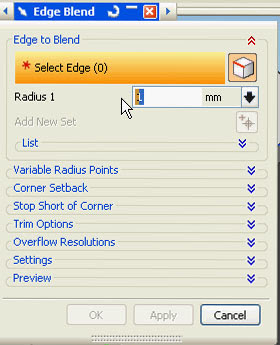

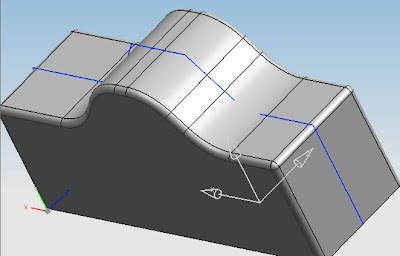

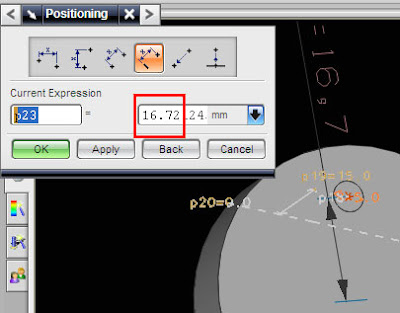

NX design is intelligent – the productive environment organizes tools, commands and information in straightforward workflows that direct the designer’s input to accomplish tasks very efficiently. On-screen displays provide instant feedback and convenient user input control without diverting attention from the task at hand. Part and assembly navigation aids enable designers to quickly comprehend the structure and techniques used to create product models. To reduce of error, NX provides previews for design commands, helping designers to proceed with confidence.

Structured

NX goes far beyond traditional CAD. Using process automation and knowledge capture tools, NX enables reusable and disciplined processes when required. This directly supports processes like lean design, design for six sigma, component and process reuse, and adherence to organizational and industry standards. NX enables companies to balance structured, repeatable best practices with the flexibility they need to move innovation forward.

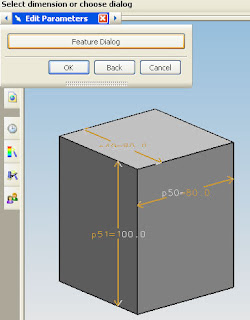

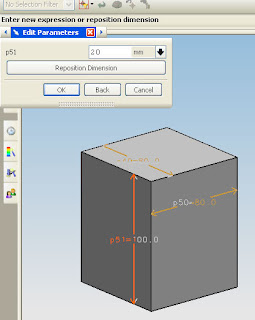

NX captures design intent through intelligent user input methods, enabling intelligent design modifications and model updates. It leads the designer through an intuitive process of querying ambiguous design decisions that need to be made when changes occur.

Managed

The seamless integration of NX design with data and process management capabilities ensures a continuously up-to-date and synchronized digital product model for the entire team to use. The NX Engineering Process Management manages and protects your product data with access and security controls. It also helps manage product complexity with automated bill of materials management and synchronization, product configurations, options and variants.

Intuitive workflows in NX present tools to the designer when they are most needed, with real-time feedback.

03:52

03:52